Windletter #117 - Dongfang Electric (DEC) installs the largest wind turbine in the world: 26 MW of capacity and a 312-metre rotor

Also: David versus Goliath, painting one blade black, DEC installs the largest wind turbine in the world, Luxcara switches from Mingyang to SGRE, and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

A new season begins and we’re back. I hope you’ve had a wonderful summer and managed to rest and recharge.

In my case, the coming months look really exciting both personally and professionally. And exciting months are ahead for Windletter too. Stay tuned!

During this break, literally everything has happened in the sector, and the truth is I’ve got loads of news saved up. I’ll see how I can organise it, but in the next few editions I might include news that’s not strictly up to date but still worth mentioning.

As always, even if we’re not the first, we’ll try to explain the context, give details, and cite sources where you can dig deeper. I’m thinking about topics like Ørsted’s troubles, the return of the Siemens Gamesa 5.X, motherf*cking wind farms, and more.

If you don’t want to miss it, subscribe 🙂

That said, before the summer break we published a couple of editions that I’ll leave here in case you missed them:

Windstory #18 – The best wind turbine transport videos to enjoy this summer (it's still summer, so you can keep enjoying them 🙂)

Windletter Insights – End of the 24/25 season (reflections on another season coming to a close)

Alright, now let’s get into this week’s news (I’ve been looking forward to saying that again, haha).

🏗️ Dongfang Electric (DEC) installs the largest wind turbine in the world: 26 MW of capacity and a 312-metre rotor

Dongfang Electric (DEC) has completed the installation of the largest wind turbine in the world, the DEC 26MW-312 HH185.

As the name itself suggests, we are talking about a turbine with 26 MW of capacity, 312 metres of rotor diameter and 185 metres of hub height. According to Dongfang, it has been manufactured with a fully independent (understood to mean 100% Chinese) and controllable supply chain.

At the beginning of the month, the first photos of the blade transport were circulating from the port of Penglai, in Yantai (Shandong). Each blade is 153 metres long and weighs 83.5 tonnes. It is the first time in history that 150 metres of length have been surpassed.

The record for the longest blade until now was held by the 147-metre units from Sinoma, manufactured for Goldwind and its GWH300-20/25MW.

As some of you may recall, in Windletter we already reported that these blades from Dongfang Electric had passed the static tests. Since they have now been installed on the prototype, they should also have passed the fatigue tests. In the post we dedicated to this topic before the summer break, you can find a video of the manufacturing process.

Speaking of manufacturing, it is important to remember that producing this type of blade is anything but simple. Several Chinese manufacturers have faced reliability issues with their first units of this kind.

Without going any further, the prototype of the Mingyang MySE18.X-20MW, with a 292-metre rotor, suffered the breakage of two blades just a few months after its commissioning. The news went so viral that even Mingyang had to issue an official statement on LinkedIn to explain the incident. And they have not been the only ones with problems. But that’s another story.

Returning to the case of DEC, it is striking to see how the blades do not even fit in the transport vessel and clearly extend beyond the cargo area.

In recent days, the first images of the installation process have also been circulating online, along with some additional technical data on the components.

It is an MSPMG wind turbine (medium speed permanent magnet generator).

The nacelle + drivetrain assembly weighs 562 tonnes and was lifted in one piece using an XGC88000 crane.

The hub weighs 145 tonnes and each blade 83.5. The rotor, in total, around 395.5.

The tower, made of tubular steel, is divided into 8 sections. The first section weighs 240 tonnes and has a diameter of 12 metres. In a version designed for offshore installation, the number of sections should be significantly reduced, as it would not face the same onshore logistical constraints.

A video of one of the blades being lifted has also been leaked, probably recorded by one of the workers on site. As always, much of this content has reached me through Gang Wang on LinkedIn, who always keeps us up to date with the details of what’s happening in China.

And finally, we’ve seen a corporate, “marketing-style” video, with epic music, showing the entire prototype installation process.

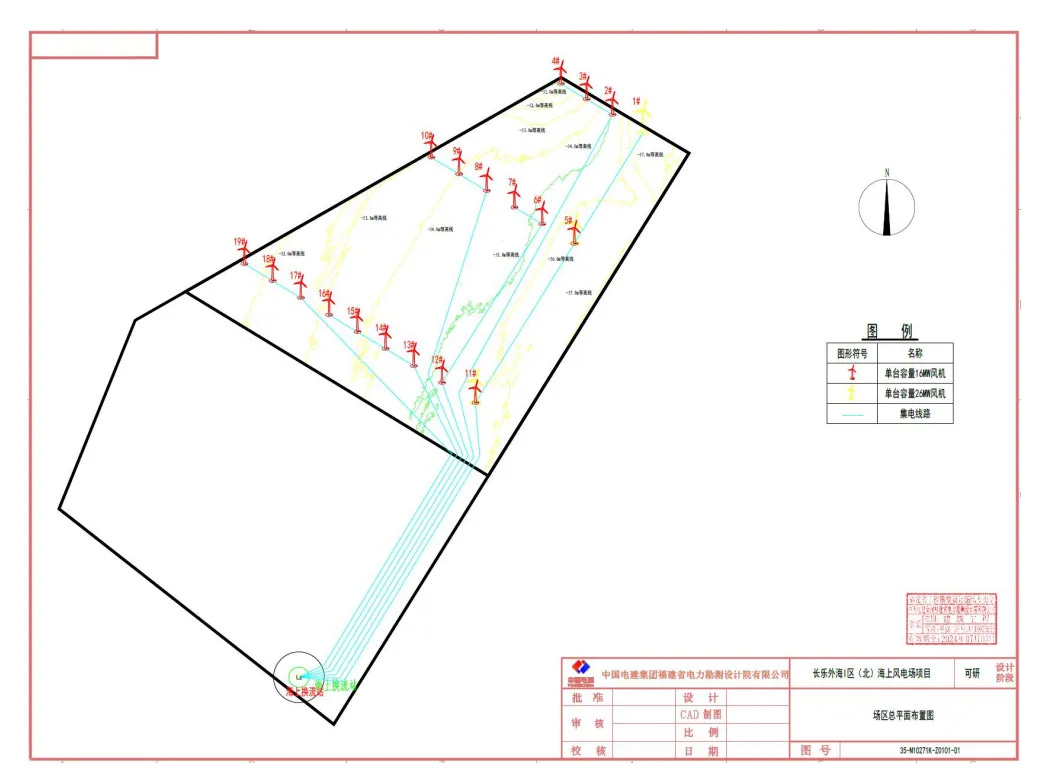

But the story doesn’t end there. DEC already has plans to install a unit of this turbine offshore as part of the Changle Offshore I (North) wind farm, located about 60 km off the coast of Fujian, in the Taiwan Strait.

As can be seen in the environmental impact study, the wind farm will include 18 wind turbines of 16 MW and one 26 MW prototype (the yellow unit barely visible in the upper-right corner of the image below).

Interestingly, the study mentions a rotor diameter of 310 metres, instead of the 312 metres cited in other sources. The hub height will be the same as the onshore prototype: 185 metres.

I’m attaching the full environmental impact report, in case anyone wants to take a look (just a heads-up: it’s 356 pages in perfect Chinese).

And for those interested in what’s coming out of China in terms of extra-large turbines, I recommend taking a look at the following article:

🛡️ Offshore wind farms could contribute to the defence of Europe

Many of you probably remember that last November the Swedish government announced, surprising many, that it was cancelling the development of 13 offshore projects with a total capacity of 32 GW, all of them located in the Baltic Sea.

Most of the projects were in an early stage of development, but it was a heavy blow for the sector in Europe.

The reason for this cancellation, according to the government, was that the installation of those wind farms could have unacceptable consequences for Sweden’s military defence, which, let us not forget, shares a border with Russia, with Kaliningrad on the other side of the Baltic Sea.

Even back then, we noted that it was quite surprising that other countries with access to the Baltic Sea and similar areas had not raised objections to this type of project.

Euractiv explains that, after Finland and Sweden joined NATO, rising tensions with Russia have turned the region into a geopolitical hotspot.

However, Poland, unlike Sweden, sees offshore wind as a defence opportunity. And Poland is one of the EU countries with the highest defence spending and, due to its geographical position, is investing the most resources in this area.

In this new scenario, offshore wind farms in the Baltic are set to play a key role. Projects like Baltic Power, in Polish waters and located less than 200 km from Kaliningrad, will equip their turbines with radars and sensors following national defence guidelines.

Apparently, the radars installed on the wind turbines are capable of detecting drones several kilometres away. It is worth remembering that drones have become one of the most commonly used weapons in current armed conflicts. You can find more information on Euractiv.

🎉 Tetrace celebrates its 15th anniversary consolidating its growth

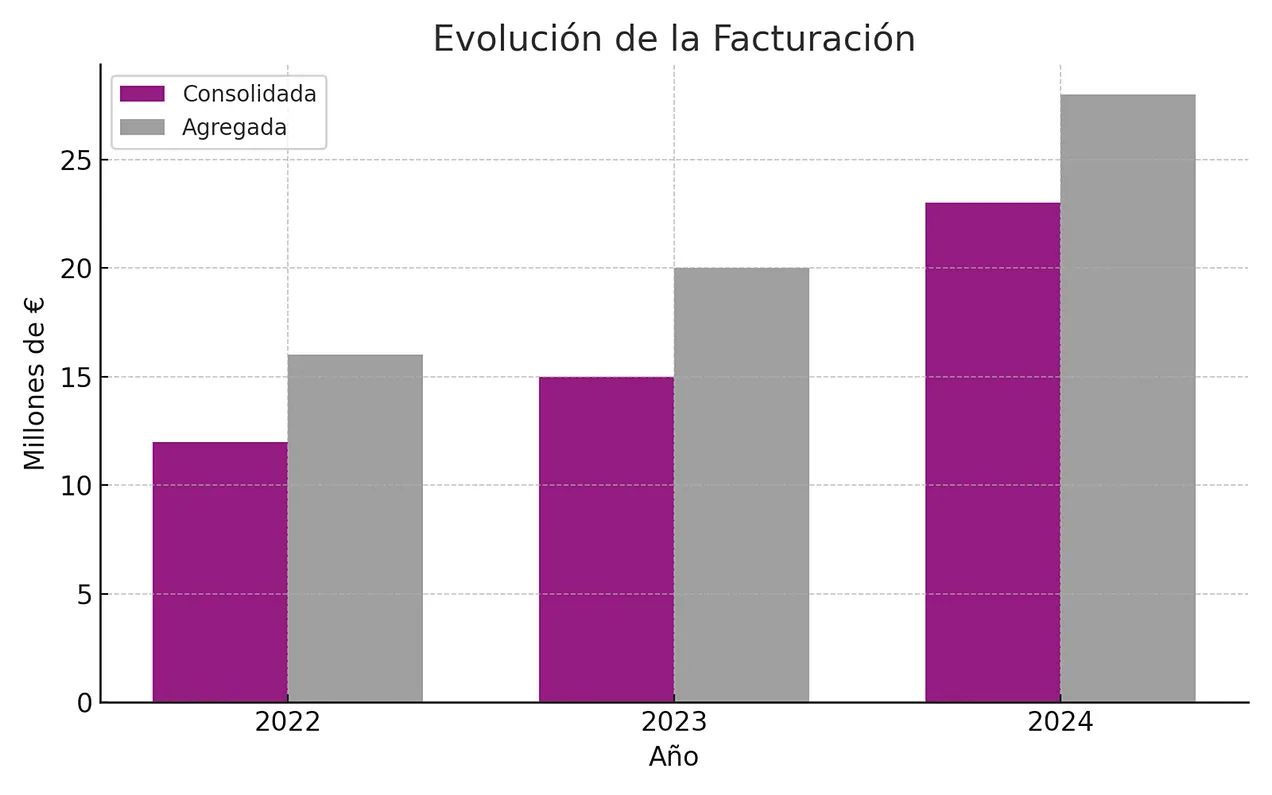

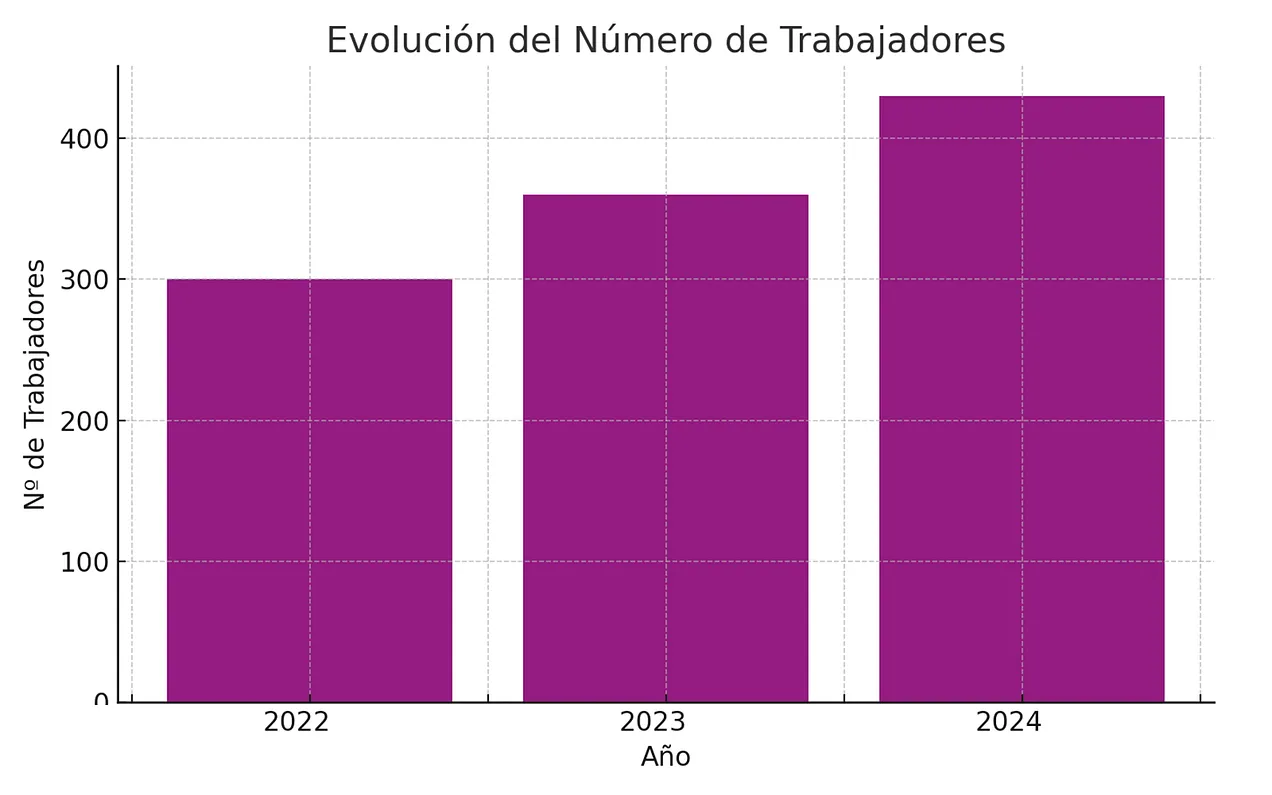

Our sponsor Tetrace has presented its consolidated results for the 2024 fiscal year, a fantastic year for the company according to its CEO, Ciro Larrañeta.

The company’s main and most important KPI is that they managed to close the year with zero accidents, a true achievement in such a complex sector as wind energy, where work at height, confined spaces, suspended loads, and electrical hazards are commonplace.

In terms of turnover, the company closed with €23 million in consolidated revenue (€28 million aggregated) and an EBITDA of €3.5 million. This represents a revenue increase of over 35% compared to the previous year, and an even higher growth in EBITDA.

At the end of 2024, 430 people were directly part of the company, spread across the offices in the 17 countries where it has a presence. Notably, in 2024 the Canadian subsidiary was established, following the latest openings in Australia (2023) and the United States (2021).

Employee well-being indicators exceed 4.2 out of 5, although management acknowledges there are areas for improvement.

Among the most relevant milestones in recent years are:

Opening of the corporate warehouse in Torres de Elorz.

First blade replacement using Nabrawind’s craneless Bladerunner technology.

Capital investment in Tetrace by COMANSA as a partner.

Full dismantling of a wind farm.

Recently, the company also created TAES, a new R&D unit within the Navarre R&D&I System (SINAI). This is part of Tetrace Group’s commitment to building a dedicated research and development team.

For the current year, the company expects to surpass the 500-employee mark.

⚖️ David versus Goliath: the spectacular size difference between a Nordex N60-1.5MW and a Sany SI-23010

In repowering projects, the evolution of wind technology is usually evident in the numbers: the new turbines that replace the old ones are much larger and more powerful.

What’s not so common is being able to appreciate that difference visually, since old turbines are usually dismantled before the new ones arrive on site. The presence of both generations side by side is quite rare.

The following images show a direct comparison between a Nordex N60 of 1.5 MW (60 metres of hub height) and an imposing Sany SI-23010, with 140 metres of hub height.

The contrast is overwhelming: from a rotor diameter of 60 metres to no less than 230 metres.

This wind farm belongs to a period when Western turbine manufacturers still had a direct presence in the Chinese market. Today the picture is very different: China has become a manufacturing hub for many of these OEMs, but it is no longer a market where they actively compete.

It’s striking that these Nordex turbines are about to be dismantled after just 17 years of operation when, according to some comments, they are truly robust machines.

🌊 India cancels its offshore auctions due to lack of interest

India is the fourth country in the world by installed wind power capacity, yet it does not have a single megawatt of offshore wind. Until recently, all efforts had focused on the development of onshore wind, which makes sense given its lower cost.

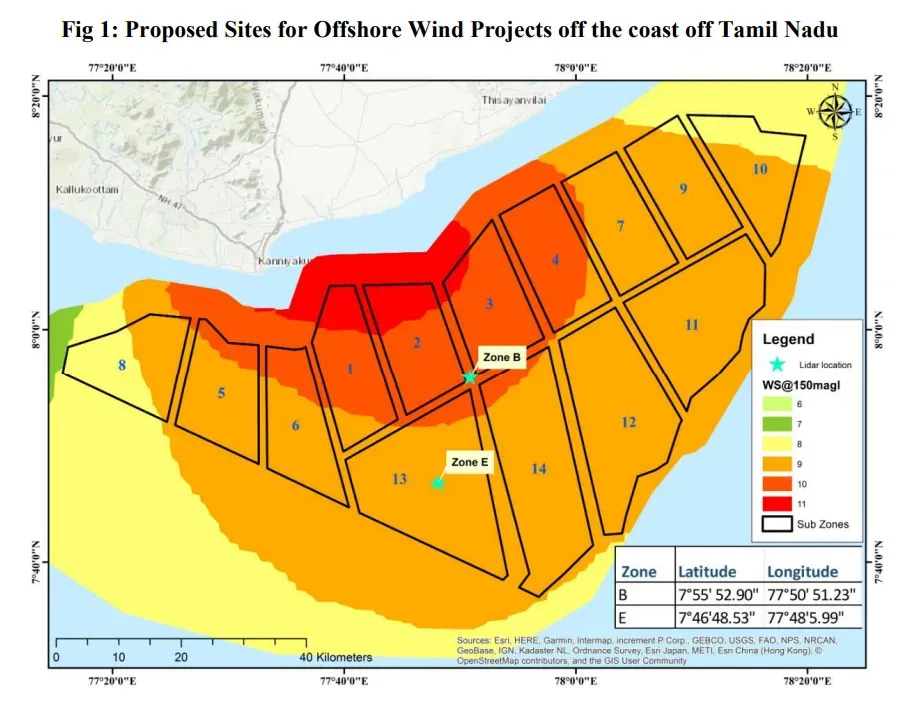

Lately, the offshore wind sector had started to move, with a 500 MW offshore wind auction in Gujarat and a 4 GW round for the allocation of maritime zones in Tamil Nadu.

However, SECI, the public company under India’s Ministry of New and Renewable Energy, cancelled both processes on 12 August.

According to several media outlets, there was a lack of interest from developers due to the following reasons:

Multiple deadline extensions in the tenders before eventually being cancelled

Doubts about the profitability of the sites

Lack of investor confidence to enter the Indian market

Insufficient political support to provide stability and credibility to the regulatory framework

Limited grid capacity to integrate large-scale projects

Absence of suitable ports for offshore construction and logistics

Considering the challenges we’ve been seeing recently in Europe, it seems clear that offshore wind in emerging countries still has a tough road ahead.

🐦 Is painting one blade black effective in reducing bird mortality?

Bird mortality is one of the most closely analysed aspects in the environmental impact assessments of wind farms, and also one of the most sensitive topics in public opinion.

For this reason, the industry is increasingly allocating resources to the research and development of preventive measures, ranging from advanced solutions with cameras, sensors and artificial intelligence, to much simpler methods. One of the latter is precisely the one we’re looking at today.

For years, a simple yet striking idea has been circulating in the sector: painting one of the three blades black could significantly reduce bird mortality at wind farms.

And this is not just a hypothesis. Iberdrola has already implemented this measure on several turbines at its Cavar (Navarra) and Zorreras (Zahara de los Atunes, Cádiz) Spanish projects, and there are other pilot programmes under way around the world.

The scientific basis comes from a study conducted in Smøla (Norway) several years ago, whose results were surprising: after painting one blade black on four turbines, bird mortality was reduced by 72%.

Similarly, RWE has carried out a pilot study on seven wind turbines at the Eemshaven wind farm in the Netherlands, over a one-year period. The report has been published openly, although unfortunately it is only available in Dutch.

According to Mario Castellanos on LinkedIn, the conclusions of the study are as follows (quoted verbatim):

No statistically significant reduction in bird collisions was observed.

This shows that general conclusions cannot be drawn from small-scale studies (Smøla).

Context matters (industrial area), and there are no universal solutions.

Further research on this specific topic is needed.

In the end, it seems clear that conclusions cannot be drawn from a single study in a single location. More research is needed. In any case, RWE’s transparency and the decision to make the results available to the industry and the scientific community are certainly to be welcomed.

We already talked about bird detection systems in Windletter issue #99, where we highlighted the work of the manufacturer IdentiFlight.

🔄 Luxcara switches from Mingyang to SGRE as preferred supplier for the Waterkant offshore wind farm

A little over a year ago, we reported in Windletter that the German developer Luxcara had selected Mingyang (and its 18.5 MW turbine with a 260-metre rotor) as the preferred supplier for its Waterkant offshore wind farm (300 MW).

In total, this was a preliminary agreement for 16 turbines of 18.5 MW, amounting to 296 MW. The news caused quite a stir in the sector.

According to Luxcara, Mingyang had been selected following an international tender launched at the end of 2023 and after a due diligence process carried out in collaboration with DNV and KPMG, covering supply chain, ESG compliance with the EU taxonomy, and cybersecurity.

However, back in June we noted that the project had come under scrutiny by the German authorities. The German Ministry of Defence expressed serious concerns about Mingyang’s involvement in the project.

Now, Luxcara has announced that, as part of the reservation agreement signed with Siemens Gamesa for its 1.5 GW Waterekke project, it has also included the reservation of 19 additional turbines of 15.5 MW for the Waterkant project.

The company explained that it “sees potential in bundling procurement and contracting processes” for the Siemens Gamesa turbines, as well as in “joint installation campaigns and coordinated operations.”

And it does make sense. Waterkant is a relatively “small” project at just 300 MW, by offshore standards. So integrating it into a larger contract could streamline the purchasing process and possibly give them access to better pricing. Additionally, when it comes to operation and maintenance, having a single turbine model is much more efficient and optimised.

How much of this is a commercial-economic decision and how much is political remains unclear.

One important detail is that Luxcara mentions 15.5 MW SGRE turbines, which, unless I’m mistaken, is the first time this model has been mentioned in the media. According to industry sources, this would be an extended version of the SG14.0-236 DD, maintaining the rotor but increasing the output to 15.5 MW.

Given the attention the issue has received in the press, Mingyang has issued an official statement on LinkedIn confirming the situation and reaffirming its commitment to the European market, where it “sees many opportunities and is supporting a number of projects in the region.”

The turbine change for Waterkant has been discussed with the relevant permitting authorities and with the Federal Ministry for Economic Affairs and Climate Action.

Waterkant and Waterekke are expected to be operational by the end of 2028 and 2029 respectively.

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.