Windletter #119 - Siemens Gamesa returns to the market with the successor of the 5.X

Also: details of the assembly of the OceanX floating prototype, wind power may not be as much of a threat to birds as it seems, soft repowering and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

The most read in the latest edition: the recovery of Nordex, the article on wind farms and fires (please, use Google Translate), and the website of the wind turbine manufacturer eno energy.

In addition, last week we published a Windstory a little different from the usual, in which we talked about Vattenfall’s latest campaign “Motherf*ckin’ wind farms.”

Now let's get on with the news of the week.

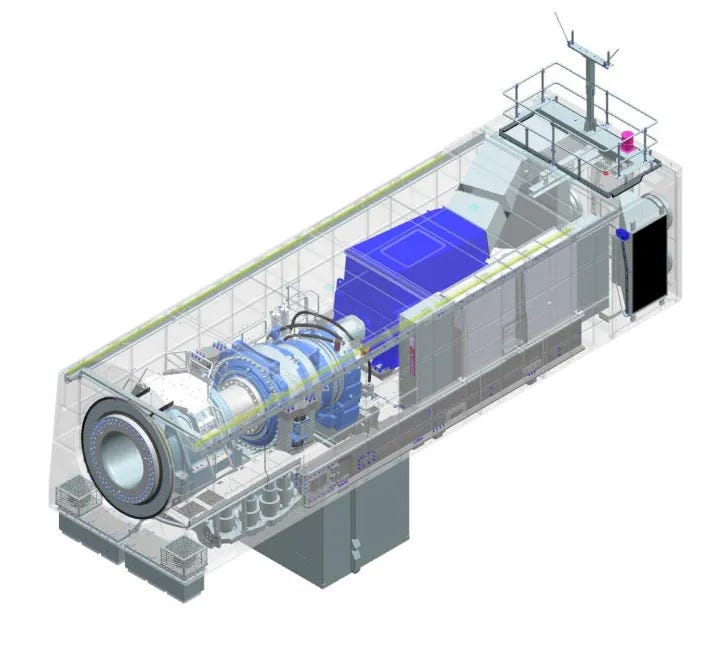

⚙️ Siemens Gamesa returns to the market with the successor of the 5.X

After almost two years on hold, Siemens Gamesa returns to the market with the successor of the SG5.X. This comeback follows that of the 4.X, which returned in September last year and recently received its first order: 8 units for the first wind farm in the Basque Country in two decades.

The SG5.X was launched on the market in April 2019, coinciding with the WindEurope fair in Bilbao. It was presented with a rated capacity of 5.8 MW and in two versions, with rotors of 170 and 155 metres.

According to statements from the company, it was the first turbine developed jointly by both “legacies,” Siemens and Gamesa, and incorporated the best solutions from each.

From the beginning, the model had a great reception in the market: it took barely a year to reach its first gigawatt sold. What was particularly striking was that SGRE was marketing so many turbines without yet having installed the first prototype of the platform.

This behaviour was common among several OEMs during the years of the so-called “race to the bottom,” where sales ran ahead of product development and which led to a generalized crisis in the industry.

The prototypes installed during the development of the SG5.X were a 155 in Alaiz (Navarra, Spain) and two 170 in Høvsøre, Denmark. Some of them were installed at the same time, or even after, the first signed sales.

By January 2023, SGRE announced on its website that the platform had reached 5 GW in sales, the vast majority corresponding to the version with a 170-metre rotor.

A significant part of Siemens Gamesa 5.X turbine orders went to the Nordic countries, which represent 3.5 GW of the total, with Sweden and Finland leading. Brazil added at least another 777 MW, and the rest was distributed in smaller contracts in countries such as Canada, Scotland, Germany or Spain.

It is possible that some of these contracts never materialized, or did so with significant delays.

After some time in operation, major reliability problems began to surface with the 5.X platform (and, to a lesser extent, the 4.X), which caused multimillion-euro losses for Siemens Gamesa. According to the company itself, the failures were located mainly in the blades and in the main bearings.

Finally, in June 2023, SGRE decided to withdraw both platforms from the market, halting sales indefinitely. Practically at the same time, Siemens Gamesa was fully integrated into Siemens Energy after the takeover bid, ceasing to be listed on the Ibex 35.

Much has happened since then. Two years later, and after the return of the 4.X in September last year, it is now the turn of the 5.X to come back.

According to statements by Christian Burch, CEO of Siemens Energy, this is not a “fixed” SG5.X, but rather a machine with a deeper redesign. The literal quote reported by EnergyWatch is: “It’s definitely not just a 5.X with fixes”.

In fact, Siemens Gamesa wants to move away from the SG5.X designation and has decided that the commercial name will officially be SG7.0-170, in an attempt to dissociate it from the problematic platform.

However, industry sources point out that beyond the modifications resulting from the various problems detected in the existing fleet and installed prototypes, no major changes are expected.

As for the 155-metre rotor, it no longer evens appears on their website, suggesting that it has been removed from the portfolio. It is a machine with a much more limited market, designed for sites with stronger and more demanding winds.

The return of the SG5.X (or, rather, the SG7.0-170) to the market is undoubtedly excellent news for the sector, which needs a solid Siemens Gamesa with a competitive product offering. The more options available, the better for developers and the healthier the industry as a whole will be, since competition makes us all better.

Although it will take SGRE time to fully regain market confidence, it is foreseeable that, over time, new contracts will begin to materialize, marking the start of a new stage for the platform.

Bonus track: the first SG5.X in Spain

In the case of Spain, these large turbines (>6.X) took a little longer to arrive than in other European markets. It has been more recently that turbines in that power range have begun to be installed. Even so, at the time some projects were signed with the SG5.X, such as Iberdrola’s Iglesias wind farm or Repsol’s El Cerrato cluster.

Of course, there were surely many other wind farms where the SG5.X was the planned or processed machine, but which ultimately had to adapt and opt for another model.

Taking advantage of the holidays and the fact that “my town” (which in Spain is known as the town of your parents/grandparents) is relatively close, I went to visit Repsol’s El Cerrato cluster. Located in the province of Palencia, between the municipalities of Baltanás and Villaviudas, it is the first wind farm in Spain to install the SG5.X-170.

This was in mid-August, and the impression I got was that the wind farm was already completed at the level of “mechanical completion,” but still awaiting the “commissioning” of the turbines, or at least some of them. In fact, I was able to see several vehicles in the area from what appeared to be the EPC contractor’s staff, as well as from Siemens Gamesa.

In reality, it is a cluster of three wind farms, with a total of 6 x SG4X-145 and 19 x SG5X-170.

Here is a photo taken from the top of Baltanás, with the church tower in the foreground and the wind farm in the background.

And a short video at the foot of the turbine:

Your invitation to Greencities 2025 – Where the future of urban management begins!

The countdown is on for the benchmark event in business, innovation, and knowledge for companies and territorial managers. Greencities, Urban Intelligence & Smart Mobility, returns on October 1–2 in Málaga.

Join technology leaders, institutions, and governments, expand your professional network, and discover the latest solutions in sustainability, mobility, and urban digitalization.

Register for free as a professional attendee and gain access to the exhibition area and a top-level program featuring inspiring talks from leading experts.

Register now and be part of the future of territories.

🚄 CRRC Zhuzhou presents a DFIG machine of… 12 MW!

CRRC Zhuzhou has successfully installed the prototype of an offshore wind turbine with 12 MW of power, blades of 126 metres (so the rotor will be around 250–260 metres), and a hub height of 150 metres.

The figures are not particularly impressive compared to what we are used to, although, as is often the case with Chinese turbines, what stands out is the rotor/nominal power ratio, which is quite low (226–244 W/m²) compared with European standards. As a reference, a V236-15.0MW has a specific power of 343 W/m².

Lo más relevante de la noticia es que se trata de un aerogenerador con tecnología DFIG o doblemente alimentada. Muchos fabricantes chinos siguen apostando por esta tecnología en el escalado de sus productos, mientras algunas voces en la industria indican que la tecnología DFIG tiene algunos problemas de escalado cuando se alcanzan ciertas potencias.

Según comenta la propia CRRC, la tecnología de doble alimentación se basa en la amplia experiencia de CRRC en transmisión, conversión y control de alta potencia en el sector ferroviario.

Although it is worth recalling that a few months ago we mentioned that Windey had installed a 16 MW wind turbine with DFIG technology.

On drivetrains, you can read the following article:

🌊 Video with details of the assembly of OceanX, MingYang’s 16.6 MW dual-rotor floating platform

More than a year ago, we published in Windletter an extensive analysis of MingYang’s spectacular OceanX floating platform. A true work of engineering art that went around the world due to the spectacular nature of its design.

Now in operation, it is the most powerful floating platform in the world with 16.6 MW (2 Mingyang MySE8.3-180 8.3 turbines).

A long video (> 8 minutes) has now circulated online showing a multitude of details of the entire process, from the assembly of the platform in port to the launch, including the installation of the turbines. The number of hours and the manpower required just to build the floating platform is immense. The video is certainly worth watching.

The OceanX platform, also known as Nezzy², is a design by Aerodyn licensed to MingYang. In fact, Aerodyn had already tested a 1/10 scale prototype in Germany in 2020.

One of the interesting aspects of this design is that in this case MingYang is the designer of both the wind turbines and the platform.

🐦 Wind power may not be as much of a threat to birds as they want us to believe

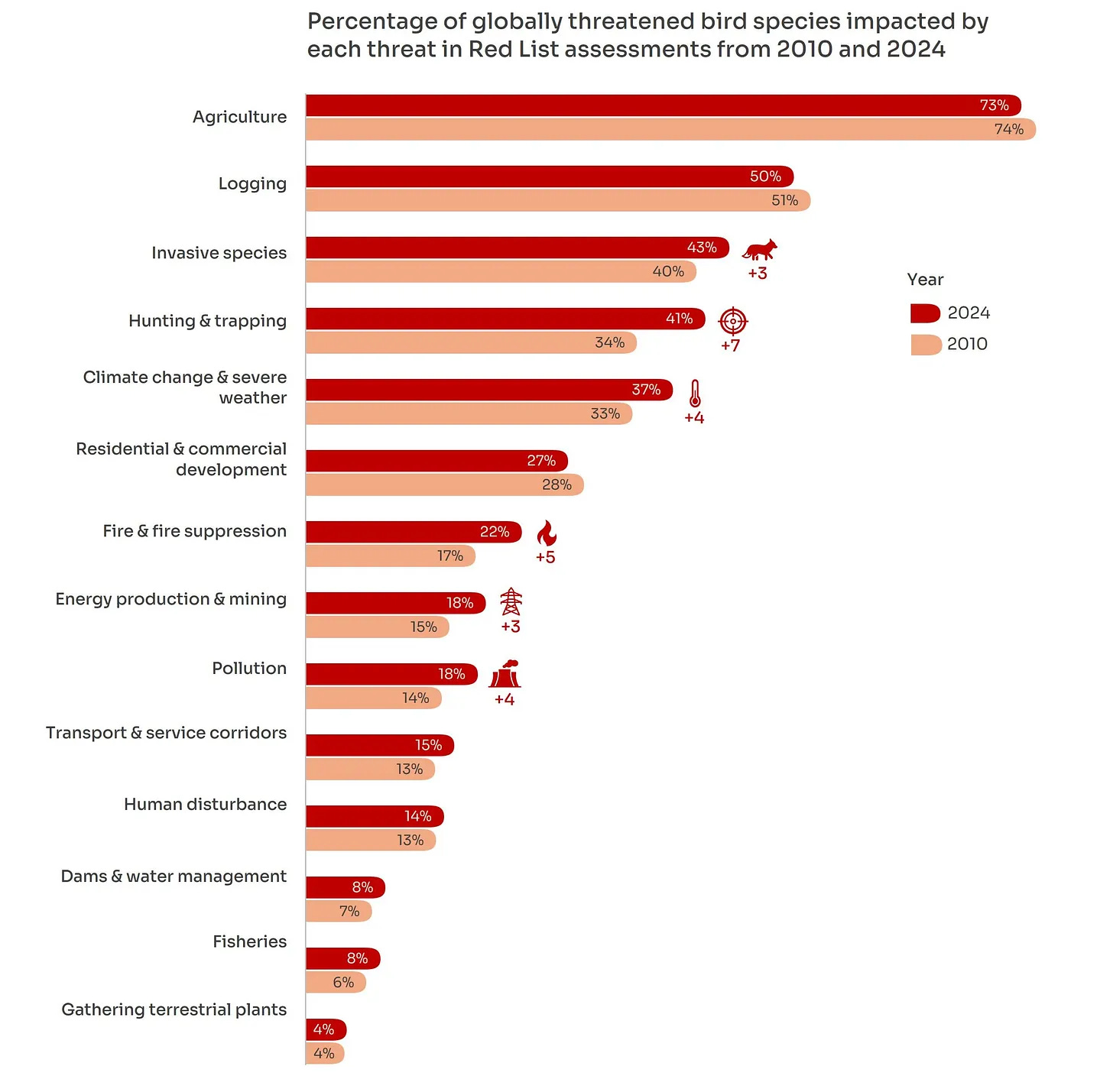

BirdLife International, responsible for assessing the extinction risk of more than 11,000 bird species, has published its annual update on protected species with some very interesting data.

Specifically, in the press release they published a chart that particularly caught my attention.

The analysis of the data from BirdLife’s most recent species assessments reveals that the threats affecting the largest proportion of globally threatened bird species are, in descending order: agriculture (affecting 73% of species), logging (50%), invasive alien species (43%), hunting and trapping (41%) and climate change (37%).

Energy and mining stand at 18%, of which wind power will be “responsible” for an even smaller percentage.

Of course, this does not mean that renewables cannot affect birdlife and that it is not something to analyse and mitigate, but there is a big difference between that and turning them into the number one target and demanding much more from them than from other activities.

My impression is that a lot of energy is spent on pointing out how bad wind turbines are and how many birds they kill, while very little is said about agriculture or invasive species, which are the first and third causes respectively.

🔧 Soft Repowering: replacing the nacelle of a wind turbine with a new one… from a different manufacturer!

The replacement of a complete rotor and/or a complete nacelle of a wind turbine to increase its power and/or production is popularly known as partial repowering. Historically, it has been relatively popular in the United States, but not so much in Europe. Depending on the scope, there are different options:

Rotor

Rotor + nacelle (or some drivetrain components)

Rotor + nacelle + last tower section

In recent weeks, a soft repowering project has been carried out in Sweden, a strategy that allows upgrading/retrofitting wind turbines while keeping the original tower and foundation.

The project, carried out by the company Business in Wind, began with the removal of a 3 MW Sinovel, which was replaced by a Vestas V112. This week, a 2.5 MW Führländer was also dismantled.

The Vestas V112 turbines used in this project came from Germany, where they were dismantled in good condition. After a light refurbishment, which included replacing the control systems with DEIF controllers, they are ready to begin a second life at this Swedish site.

To couple the new nacelle to the old tower, it is usually necessary to replace at least one section of the tower. This new segment serves as a transition piece between the original structure and the new nacelle. In the photo I leave below, you can see the peculiar shape of this new section, wider at its base and narrower at the top.

Among the benefits of this repowering, it is noted that these turbines now feature a reliable model with wide spare parts availability. In this way, the service life of the wind farm is extended with minimal investment and lower environmental impact, while ensuring good operational performance and ease of maintenance with a model that has a long track record.

Apparently, Business in Wind has done similar work installing an Enercon E-82 on a Führländer tower.

I would really love to see the engineering work behind this kind of modification.

🌕 Picture of the week: the crane that held the moon

As you already know, every now and then we bring some beautiful wind-related photos here.

This week’s comes from Cristian Gatti, who, playing with perspective, managed to capture this curious photo where the main crane seems to be lifting the moon.

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.