Windletter #123 - A wind turbine with a 300-metre hub height

Also: Nordex raises its forecasts for 2025, inspecting rotors with drones and LiDAR, another tattoo inspired by wind energy Spanish version, and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

The most read pieces from the latest edition were: the video of Ming Yang’s OceanX assembly, DTU’s poster on why large wind turbine blades fail, and the article on the fading hopes for floating wind energy.

In addition, last week we published an interesting analysis of the CITE25 Congress held in Pamplona, focused on defending the European supply chain. I also recommend the article on the dismantling and material management of the Muel wind farm by our sponsor RenerCycle, it has performed very well.

Errata:

The world’s longest and heaviest XXL monopiles. In the last edition we mentioned that the XXL monopiles manufactured by CS Wind Offshore surpassed the 80 m installation depth barrier for fixed-bottom wind. After a message from a reader, we clarify that this interpretation was incorrect. The monopiles, up to 123.6 m long, correspond to a TP-less design (without a transition piece between foundation and tower), and their total length includes the buried section (≈40 m), the water column (≈60 m), and the flange height (≈20 m). Everything suggests they are destined for the Atlantic Shores wind farm (U.S.), with maximum depths close to 60 m.

The permanent magnets recovered from the Nordtank turbines. In the article about the dismantling of the Muel wind farm, it was stated that the permanent magnets of the Nordtank turbines were located inside the generators. After verifying the information, we clarify that these turbines did not use generators with permanent magnets, so that statement was incorrect. In reality, the magnets were used to fix electrical cabinets to the tower.

By the way, I’m sure I make more mistakes and inaccuracies in Windletter than I’d like to admit. I’m always happy for you to point them out, you can do so simply by replying to this very email 🙂

Now, let’s get to this week’s news.

🏗️ A wind turbine with a 300-metre hub height

Several times in Windletter we have talked about wind turbines with very tall towers, but we had never seen anything like this.

With a total height of 365 metres (300 m hub height), the GICON High Wind Tower (GICON-HWT®) will become the tallest onshore wind turbine ever built.

Currently under construction in Schipkau (Lusatia region, eastern Germany), it will be the second-tallest structure in the country, just behind Berlin’s TV Tower (which is barely 3 metres taller).

The tower as a whole represents an impressive engineering challenge: it will contain over 2,000 tonnes of steel and around 22,000 individual parts.

Design and technical data

As is often the case with large towers, the GICON-HWT breaks away from the traditional tubular design. Instead, it uses a four-legged steel lattice structure reminiscent of high-voltage transmission towers.

But how is it possible to mount the nacelle, hub, and rotor on a turbine with a 300-metre hub height? Some of you may be wondering. And the truth is, I have my doubts that there are cranes in the market capable of doing so, at least not the standard mobile ones used in the wind industry.

That is why the design includes an innovative dual telescopic tower system: inside the outer tower sits an inner tower on which the nacelle and rotor are first assembled at an intermediate height (similar to conventional turbines, around 150 metres in this case).

Once the machine is fully assembled, the inner tower is raised “like an elevator,” using the outer structure as a guide, until it reaches the final 300-metre hub height. The concept is clearly shown in the following video.

In theory, during major corrective maintenance, the nacelle could be lowered again to the intermediate position, allowing access with standard cranes. In any case, it doesn’t look like a simple operation.

At the top of the tower, a Vensys 126 turbine of 3.8 MW will be installed, modest compared to today’s models in Germany, many of which already exceed 6 or even 7 MW.

Still, that’s quite impressive for a prototype of this nature. Remember that today, the tallest commercial towers are around 200 metres, typically hybrid steel-concrete structures.

A considerable increase in production

As you know, greater height allows access to stronger wind resources. The simplest and most common way to express this relationship is through the power law wind profile:

where:

v1v = wind speed at a reference height h1h_1h1 (e.g. 10 m)

v2v = wind speed at another height h2h_2h2

α = wind profile exponent, depending on surface roughness and atmospheric stability

In simple terms, the increase in wind speed with height happens because:

Air friction with the ground (vegetation, buildings, terrain) slows the wind near the surface.

As we ascend, friction decreases and the wind accelerates until reaching a more “free flow.”

And what does this mean in practice? According to GICON, this turbine is expected to generate around 18 GWh per year, equivalent to a capacity factor of roughly 55%, comparable to offshore turbines. That’s easily more than double the output of a conventional tower height.

To reach this point, the GICON team first had to demonstrate the feasibility of operating their design at 300 metres and confirm that wind conditions at that altitude behaved as expected.

To gather the most accurate data possible, GICON installed in 2023 the world’s tallest wind measurement mast, standing at 300 metres. It can even be seen clearly on Google Maps.

Future

Without a doubt, this is an ambitious project that takes wind energy to a new level. Never before has a tower of this height been built, and the telescopic design adds mechanical complexity.

I also wonder what operation and maintenance will look like, surely new safety and logistics procedures (elevator systems, fall protection, etc.) will be needed. Still, climbing up there must be quite an experience.

The prototype is expected to be commissioned in the summer of 2026. We’ll be following its progress closely in Windletter. If you don’t want to miss it, make sure to subscribe.

For those who speak German, here’s a video from a local TV station, and also a presentation I came across online.

📈 Nordex raises its financial outlook for 2025

Nordex is on a roll. After solid second-quarter results confirming its recovery, the company has once again exceeded expectations in Q3 2025. In fact, just days before publishing its figures, it had already revised its annual guidance upwards.

The company now expects an EBITDA margin between 7.5% and 8.5%, compared to the previous range of 5% to 7%.

The rest of the indicators remain unchanged:

Sales: €7.4 – 7.9 billion

EBITDA margin: 7.5 – 8.5% (previously 5 – 7%)

Working capital ratio: below –9%

CAPEX: ~€200 million

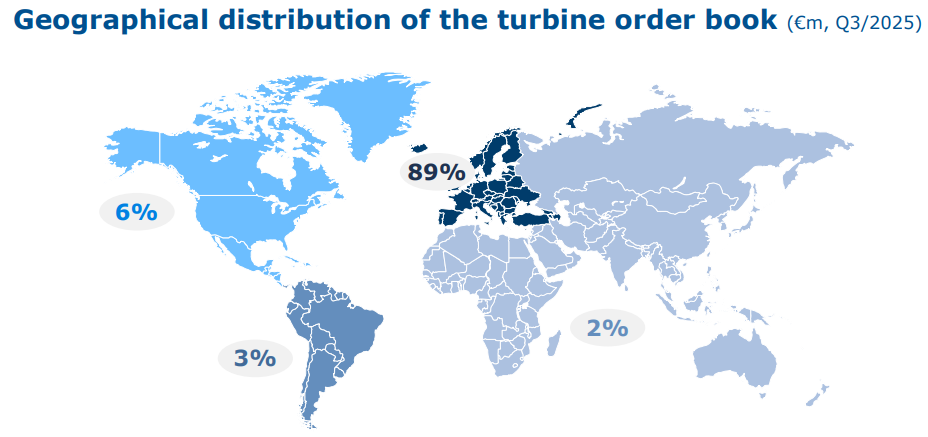

In the third quarter, Nordex recorded orders worth €2,012 million, a 27% increase compared to the same period last year. Contracts came from 16 countries, with an average price of €0.93 million/MW, practically stable compared to 2024. The strongest markets of the quarter were Germany and Canada.

It’s particularly interesting to see how Nordex is capitalising on its service business, where it has increased its EBITDA margin by 2.6 percentage points in just one year, reaching 18.6%.

Another noteworthy fact: 89% of its order backlog is located in Europe (including Turkey, where the company has a strong presence).

Those interested in reviewing the results can do so here.

Nordex is an interesting case, as it remains today the only publicly listed manufacturer focused exclusively on onshore wind turbines, allowing a clearer view of its figures and a better understanding of the sector.

For more background on Nordex’s current situation and how it reached these numbers, you can read this excellent article by Kiko Maza.

🇩🇪 Germany awards 3.4 GW of wind power in its latest onshore auction

Germany continues to consolidate its leadership in onshore wind, acting as Europe’s true driving force.

In its latest auction, held on August 1, 2025, the country awarded 3.5 GW of new capacity. The round registered a high level of competition, with 604 bids totalling 5.7 GW against a tendered volume of 3.4 GW.

Award prices ranged between €63.9/MWh and €66.4/MWh, with a weighted average of €65.7/MWh. This represents a slight improvement compared to the previous round (€68.3/MWh) and remains well below the maximum ceiling of €73.5/MWh allowed in the auction, reflecting the maturity and competitiveness of the German wind sector.

By region, North Rhine-Westphalia led the awards with 817 MW across 105 projects, followed by Lower Saxony with 800 MW in 73 projects and Brandenburg, which reached a record 609 MW across 89 projects.

One striking feature of the German market is its level of fragmentation, with a high number of small wind farms. This structure encourages diversification and competition among developers, although it also limits economies of scale, which can affect final costs.

That said, analysing the awarded data reveals that some developers have single-turbine projects located within the same area, likely due to permitting or tendering constraints that make this strategy necessary.

The next and final auction of the year was scheduled for November 1.

Official auction information can be found here.

📚 3 articles you should read to learn about floating wind

Carlos Martin Rivals, General Manager of Floating Wind for Europe and APAC at Dajin Heavy Industries and former CEO of BlueFloat Energy, has published several articles on his LinkedIn profile in recent months that are truly valuable for anyone wishing to deepen their understanding of the floating wind industry.

The first one explores the value of pre-commercial projects, highlighting their essential role in technological maturity, cost reduction, supply chain development and the bankability of future large-scale projects. It also reviews the operational wind farms around the world that are paving the way toward the global commercialisation of the technology.

The second focuses on the diversity of floater designs (mentioning more than 100 concepts worldwide) and how the sector will gradually move toward technological convergence, concentrating on a limited number of dominant designs. It also notes that semi-submersible configurations are gaining ground as the preferred choice for commercial projects.

Finally, the third article addresses the industrialisation of floaters, analysing the different manufacturing approaches: flat-plate versus tubular structures, and welded versus mechanically assembled processes.

For anyone interested in understanding the evolution of floating wind, these are highly recommended readings.

📡 Inspecting offshore wind turbines with drones and LiDAR

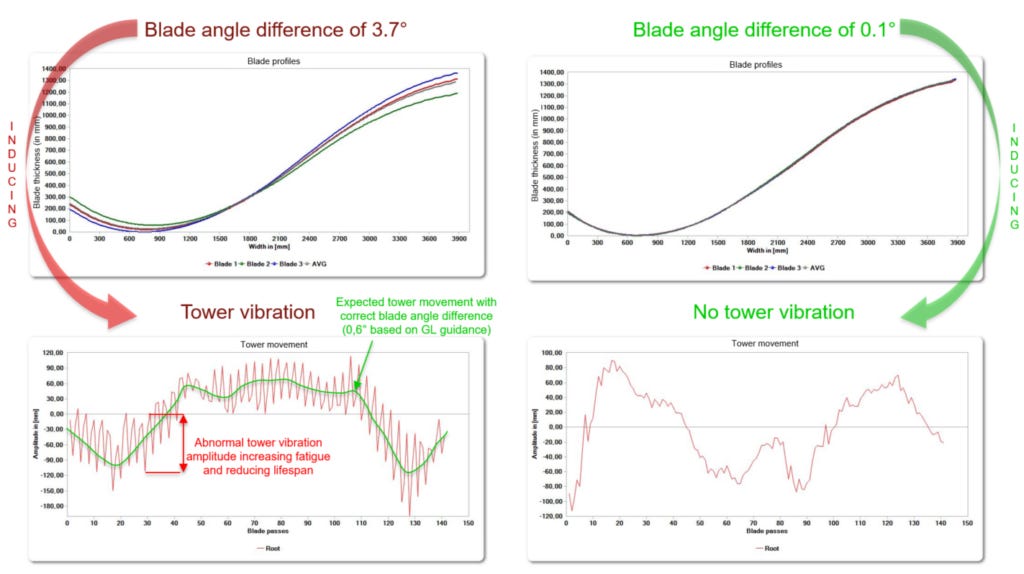

I found the following video from Alpha Wind very interesting. The French company offers a solution to verify the pitch angle of blades in operating wind farms.

In the video, one of their drones, equipped with LiDAR technology, performs an inspection on a turbine at the Saint-Nazaire offshore wind farm, specifically on a Haliade 150-6MW.

The drone, which takes off directly from the maintenance vessel, positions itself in front of the turbine’s rotor and captures all the necessary data.

A misalignment in the pitch angle causes two main problems:

Loss of generation, since the blade is not precisely positioned to achieve the ideal power curve and therefore the maximum energy output.

Increased vibrations, which are transmitted through the structure, leading to a reduction in the turbine’s service life.

🌀 The DEC 26MW-312, the largest wind turbine in the world, is energised

Dongfang Electric (DEC) has completed the commissioning of the world’s largest wind turbine, the DEC 26MW-312 HH185.

However, according to Eize De Vries, the rotor diameter of the H26-313 prototype is actually 313 metres, one metre more than the originally announced 312 m. And if Eize says so, we’ll take his word for it. Though at these scales, a metre more or less hardly makes a difference.

DEC has released a video showing the turbine spinning.

What stands out most is how slowly it rotates, although the footage isn’t long enough to accurately calculate the rpm. Some people on LinkedIn suggested around 10 rpm, while others mentioned about 7.5 rpm.

It’s very likely closer to 7.5 rpm or even less. At that speed, the blade tip would reach 123 m/s, roughly 443 km/h, an excessively high value.

In the industry, tip speed is usually kept below 90 m/s to avoid noise and excessive dynamic loads.

Therefore, to keep tip speed within an acceptable range, the actual rotational speed of the DEC 26MW-312 HH185 would be between 4.8 and 5.5 rpm.

And please, if I’ve messed up any number, let me know 🙂 (I’ll start preparing next week’s errata section).

💉 Another tattoo inspired by wind energy: the Spanish version

A couple of editions ago, we talked about the tattoo inspired by Vattenfall’s motherfckin’ wind farms campaign, inked on the leg of David Stewart, Senior Social Media and Communications Officer at RenewableUK.

That tattoo caught the attention of much of the wind industry, but apparently, it’s not the only one.

Following that post, Alejandro Álvarez, a Galician professional in the sector, replied with the Spanish version of the tattoo.

As you can see, it’s a modern reinterpretation of a scene from Don Quixote, symbolically facing the windmills. Except this time, the “mills” in the tattoo are not the traditional canvas ones from Cervantes’ story, but modern wind turbines.

Curiously, I’ve known Alejandro for a long time through the wind-energy community on Twitter, but I had no idea he had this tattoo.

Thanks for letting us share it in Windletter! 😁

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.

The 300m hub height turbines are a gamechanger for capturing those higher altitude winds with better consistency. Iberdrola's been pushing hard on their offshore projects in places like the Baltic Sea, so they're probably watching these Nordex forecasts closely. Their 2025 capacity targets depend heavily on getting this next generation of larger turbnes deployed on schedule. The Spanish market expertise they bring could really help scale these innovations across Europe.